Case Studies

Precision Hydrographic Services – Australia Western Ports

Efficient dredge surveys across Western Australia’s major ports

Survey

Precision Hydrographic Services: A Leading Hydrographic Surveying Company

Precision Hydrographic Services (PHS) is an Australian-owned hydrographic survey company that has become a leading provider of high-quality hydrographic survey services and support for port and harbor management, dredging operations, navigational safety, and more. PHS specializes in the acquisition, interpretation, and reporting of seabed information, with offices located in Adelaide and Karratha.

Investing in the Right Equipment

When PHS was established in 2008, the company needed to invest in the right equipment at an acceptable price. “Being a small company at the time, we only had three people,” explains Neil Hewitt, Managing Director at PHS. “And it was quite a large capital expenditure to invest in a multibeam system. The echosounder systems were very attractive based on capability and price, which were major deciding factors.”

Clean Data for Efficient Dredging Projects

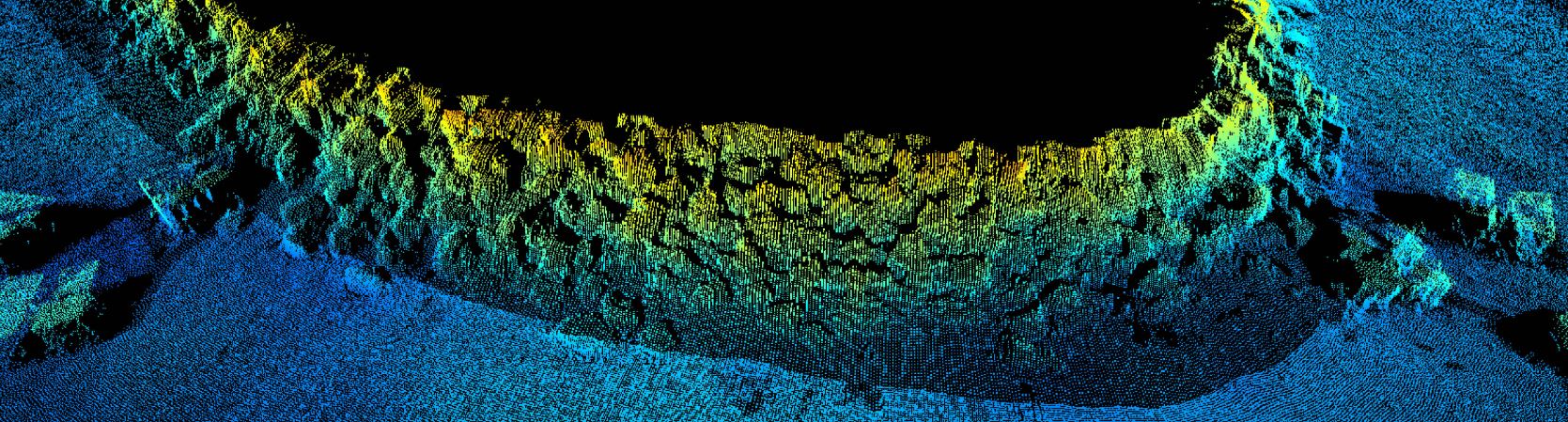

Completing dredging survey projects across three ports in Western Australia often means round-the-clock work for PHS. Among PHS’ clients is Port Hedland, the largest bulk export port in the world by tonnage. “The exports from Port Hedland are mostly iron ore,” says Hewitt. “So under-keel clearance is important … our tolerances are very tight. Dredging needs to be done very efficiently because shipping doesn’t stop for dredging to take place. When the survey systems are running during projects, they’re in operation 24 hours a day, 7 days a week … We’ve had a Sonic 2026 running that way for three months without a problem.”

Multibeam Systems for High-Quality Data

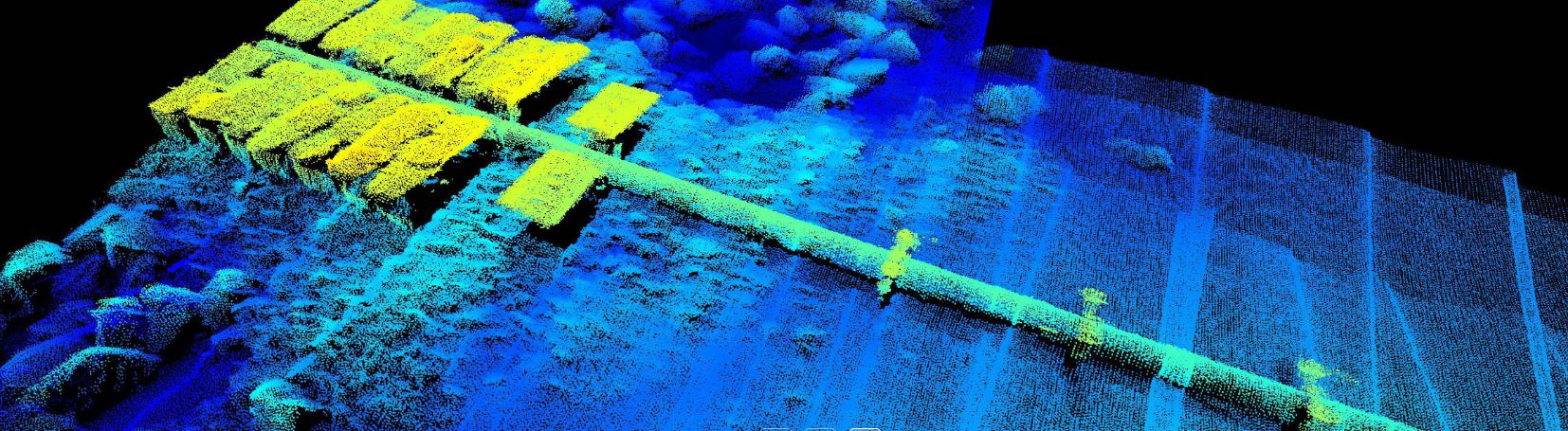

Today, PHS owns and operates three Sonic 2024s as well as a Sonic 2026, and the company’s fleet of multibeam echosounder equipment has grown over time. The multibeams are crucial in allowing PHS to carry out surveys effectively and efficiently, providing high-quality data often in time-constrained situations. “A lot of our work is in the port environment for navigational safety and dredging,” explains Hewitt. “They are shallow water, high-accuracy, high-resolution surveys – at maximum depths of about 18 meters … We were surprised to be collecting remarkably clean high-resolution data within a few hours,” he says. “We revisited an area that we had mapped with our older sonar and immediately saw the benefits of the narrow beam widths. The new system yielded a three-fold increase in resolution to our previous system. This moment set the tone for the coming years of our growth trajectory.”

Efficient Progress Surveys with Clean Data

For PHS, clean data is essential for efficient progress surveys. “For us, the cleaner the survey data that comes in, the easier it is to process. With the MBES, we can do a progress survey and have it back to the client on the dredge in about an hour. Noise in survey data can leave gaps. With clean data, however, you know you don’t have to go back and fill them in.”

Ease of Use and Responsive Service

Today, PHS runs its Sonic 2026 with the water column upgrade and has another system equipped with UHR functionality. “The team enjoys using the equipment,” says Hewitt. “We’ve taken on a few graduates over the years. They pick up using it easily. It’s testament to the simplicity of the interface and the system itself.” Hewitt concludes.