INDUSTRIES

Pipeline Inspection

The installation, inspection, and maintenance of pipelines require careful planning and evaluation, as well as regular preventative maintenance and occasional repairs.

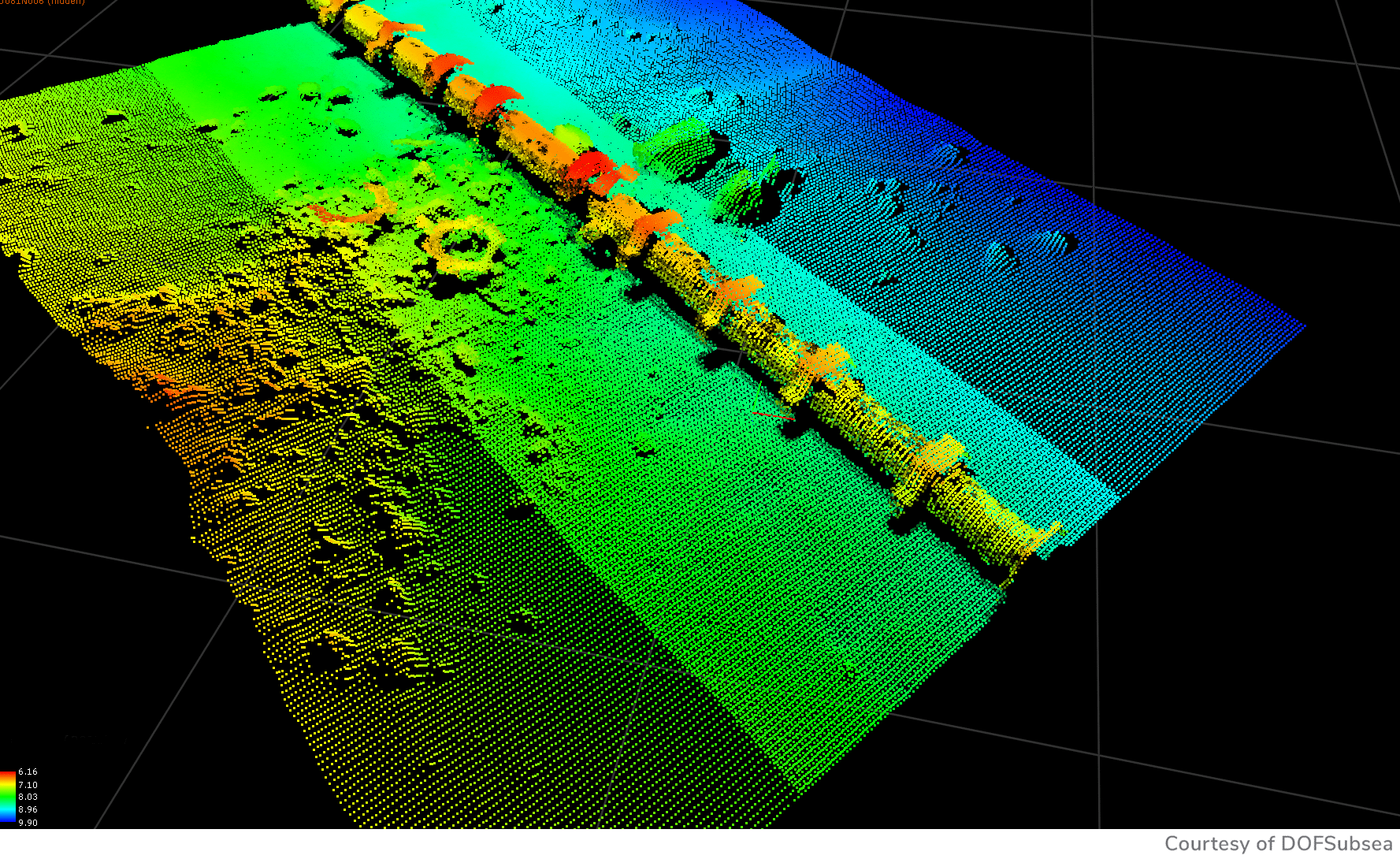

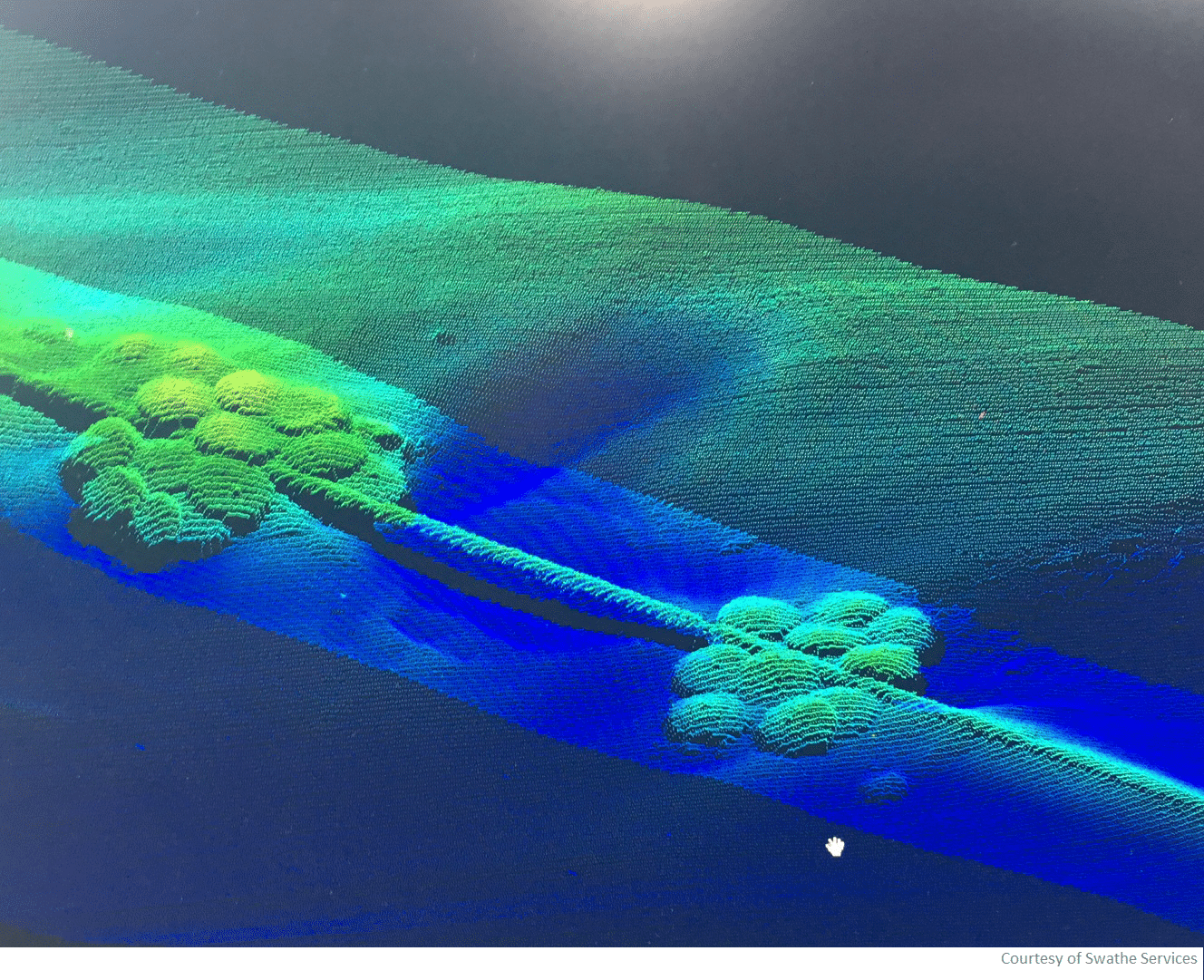

MBES technology offers faster, safer, and more precise data acquisition, which is critical for ensuring timely and accurate measurement of pipelines. The R2Sonic system includes Pipeline Mode, which enables users to survey at two different frequencies (400kHz and 700kHz) in one pass using a single multibeam echosounder. This mode provides detailed, high-resolution information about the pipeline itself, its surface, and the surrounding area, allowing operators to anticipate and quantify potential risks. With this data, pipeline operators can make informed decisions and take proactive measures to prevent damage or leaks.

Technical Modes

Technical Modes

Ultra High Density (UHD)

Ultra High Resolution (UHR)

Pipeline Mode

Related Case Studies

Related Case Studies

Survey

Detecting a gas leak

Survey

iSURVEY

Why ?

?

Besides having cutting-edge manufacturing technology within our 2,000 square meter innovation and development plant based in Malta, we provide technical support and training with a global footprint and reach.

Precision Engineering & Data Output

New levels of data quality and accuracy, with reduced data processing.

Practical & Cost Efficient

We have the right solution to meet the needs of every application.

Support & Reliability

Technical support with global reach by our expert engineering team.

Why ?

?

Besides having cutting-edge manufacturing technology within our 2,000 square meter innovation and development plant based in Malta, we provide technical support and training with a global footprint and reach.

Precision Engineering & Data Output

New levels of data quality and accuracy, with reduced data processing.

Practical & Cost Efficient

We have the right solution to meet the needs of every application.

Support & Reliability

Technical support with global reach by our expert engineering team.